304, 310S, 316, 347, 2205 Siku Tahan Karat

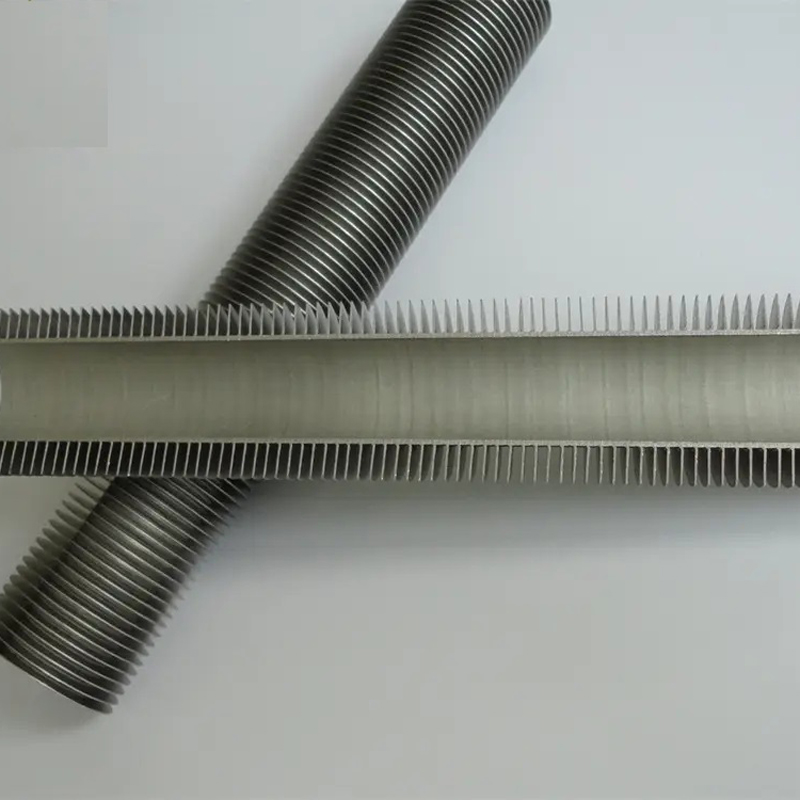

Presentasi produk

Desain lan manufaktur siku kudu nimbang akeh faktor, kayata tingkat aliran, tingkat aliran, tekanan lan suhu.Miturut sifat aliran cairan lan syarat sistem pipa, sudut mbengkongake lan radius sikut bisa diatur miturut kahanan sing nyata.Jinis siku sing umum kalebu 90 derajat, 45 derajat, 180 derajat, lsp.

Peran sikut ing sistem pipa duwe rong aspek utama.Kaping pisanan, bisa ngganti arah aliran pipa, supaya cairan bisa ngliwati sistem pipa kanthi lancar.Kapindho, sikut uga bisa nyuda mundhut tekanan ing sistem pipa lan nambah efisiensi pangiriman cairan.Pilihan sing tepat lan instalasi sistem pipa bisa luwih stabil lan efisien.

Detail Produk

| jeneng: | 45″/60″/90″/180″ Siku Equal & Reducing Tee Salib sing padha |

| Teknik: | Digawe Saka Pipa Baja utawa Plat Baja |

| Standar: | ANSI / ASME B16.9 & B16.28;GOST17375, 17376, 17377, 17378, 30753;JIS B2311;DIN2605, 2615, 2616, 2617 |

| Bahan: | Baja Karbon- ASTM A234 WPB;CT20, 09T2C;JIS G3452, SS400;ST35.8, P235GH, P265GH Baja Tahan Karat - ASTM A403 WP304/304L, WP31 6/316L, WP317/317L, WP321;08X18H10, 03X18H11, 12X1 8G10T, 10X17H13M, 10X17H13M2T;SUS304/304L, SUS316/316L, SUS321;1 4301, 1.4401, 1.4404 Duplex SS - UNS S32304;S31 500, S31 803, S32205;S32900, S31260;S32750, S32760 |

| ukuran: | 1/2″ - 24″ (mulus) & 4″-72″ (jahitan) DN15 - 1200 |

| Ketebalan Tembok | SCH5S, SCH10S, SCH10, SCH20, SCH30, SCH40S, STD, SCH40, SCH60, SCH80S, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS2- 25 mm |

| Sambungan: | Butt Weld, Socket Weld, Threaded, Seamless, Welded |

| Perawatan lumahing: | Shot Blasting;Electroplate;Hot Dip Galvanis;Paint |

| Tipe pungkasan: | Bevelled End & Plain End |

| Proses produksi: | Push, Press, Forge, Cast, lsp. |

| Aplikasi: | Petroleum / Daya / Kimia / Konstruksi / Gas / Metalurgi / Shipbuilding etc |